It’s mid-July in a New England town. You’re trying to work and you feel the sweat begin to bead on your forehead.

You’ve felt this way during the last 3-day heatwave, so you suck it up, wipe the sweat away, and continue to work. Shortly after, however, your palms become damp and you’re starting to struggle to type on the keyboard as the air is growing think and heavy from all the humidity. You find it hard to concentrate as your mind begins to wander, daydreaming of moving your office to an igloo in Alaska.

You’ve been trying to save on your electric bill, but the heat is starting to overcome you and your employees so you finally breakdown and decide to turn the A/C on full blast. Sweet relief! Your mind crawls back into the present day, the sweat dries up and you continue through your workday much more comfortably.

If you live in New England, you’ve certainly experienced similar feelings during humid heatwaves. These types of days cause buildings and houses on the grid to crank their air conditioners and fans on, increasing the amount of usage and demand for electricity on the grid. When these heatwaves sustain for multiple days, the grid eventually reaches its highest amount of electricity demand for the year, which is called a peak day. Days like this can have a brutal effect on the electricity grid as too much demand can lead to brown outs and black outs.

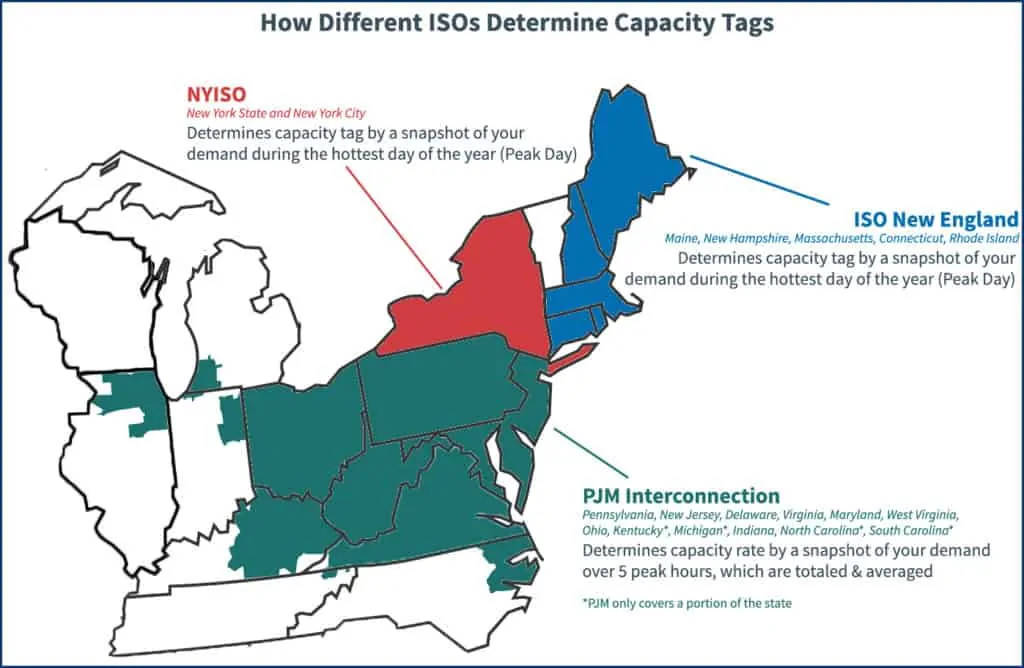

Your capacity tag is one of the main drivers of your capacity price. In New England, it is determined by a snapshot taken of your demand for electricity during one hour of one day in which residents and businesses are drawing the most electricity from the grid, i.e. the peak day. By curtailing your demand during this time, you can significantly reduce your capacity tag for the following year while also helping relieve congestion on the grid.

Our Peak Notification Service was created to help our clients manage their capacity costs down by designing tailored curtailment strategies and providing timely notifications of incoming peak events so plans can be successfully implemented. We’ve helped countless businesses lower their capacity tag through our service over the years and, in the terribly hot summer of 2019, one New England-based plastic manufacturer’s curtailment efforts reduced their capacity tag by 90%, which was the largest reduction we’ve ever seen!

Read on to discover the full story of this client’s massive success.

2019: One of New England’s Hottest Summers

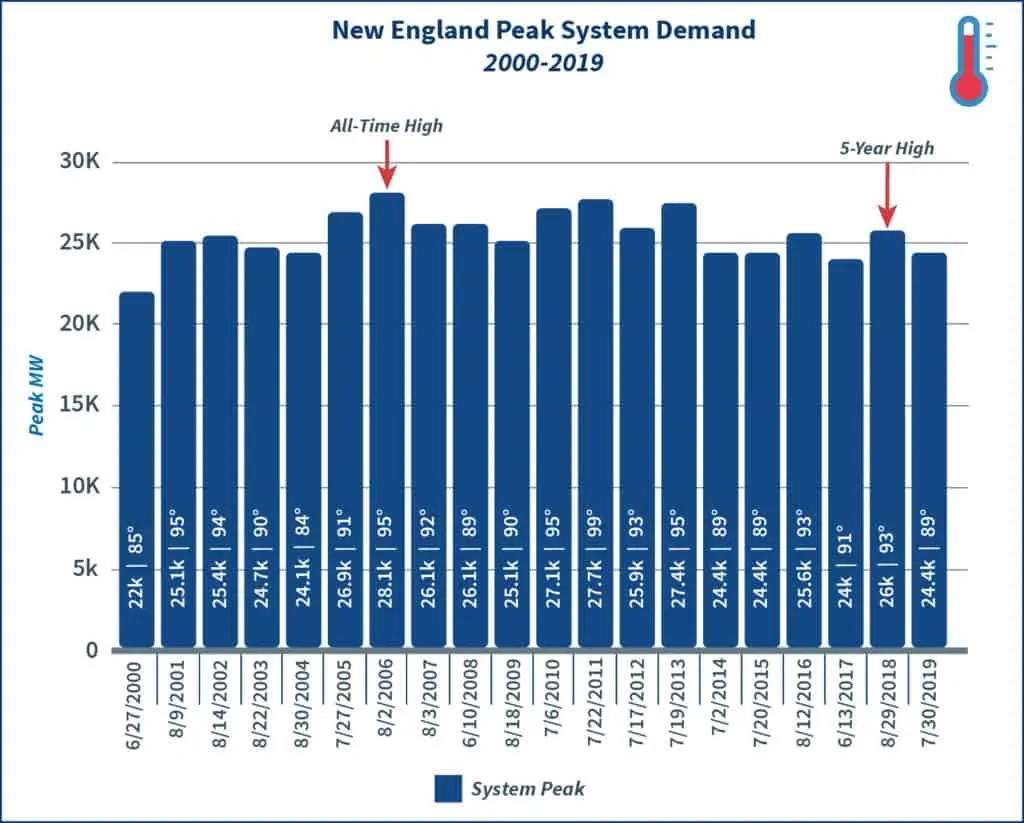

The summer of 2019 was a hot one in New England as temperatures made most northeast states achieve a top-10 record for the month of July. While July in Boston never recorded a single daily record-high temperature during the month, the persistence of the heat in the city gave rise to 12 days of 90+ degree weather, skyrocketing past the previous July record that was set in 1983.

As stated above, New England energy users’ capacity tags are set by their demand for electricity during one hour of the peak day. This usually occurs amidst sustained heatwaves during weekdays when buildings and residents on the grid are drawing the most electricity.

When a sustained heatwave hit the area in late July, we saw the peak day on the horizon and promptly notified all of our clients in our service. They all did an exceptional job of curtailing at this time, however, the actions and subsequent results of one client in particular far exceeded all expectations.

How A Plastics Manufacturer Won Peak Day

Because curtailment actions can affect business operations as many plans require them to turn off their A/C and shut down production, our service is very adamant about looking deeply into a variety of factors to determine what the likely peak will be.

This is no small task, especially in New England, because what might seem like a peak day in July could easily be beaten out by a longer or more intense heatwave in August. Due to our strict peak guidelines and stringent prediction process, however, our Peak Notification Service consistently sends out accurate forecasts and, on average, calls about 20% less peak days than many of our competitors.

On the morning of Tuesday, July 30th we noticed high temps coming in the afternoon after an unseasonably warm evening. This, combined with a heatwave consisting of temperatures exceeding 85 degrees sustained over the course of the days prior, the weather outlook for the rest of the week, data from ISO-NE’s past peak days, and a multitude of other factors, made us confident that this was going to be the day the system hit its peak in New England.

We began contacting all of our clients to inform them of the peak event on the way so they could ready and implement their curtailment strategies. Because we care about ensuring our clients are always maximizing the value of their contracts, when we haven’t received confirmation from clients on a severe peak notice, we do our best to get in touch with them.

A newer client of ours, a New England-based plastics manufacturer, had not responded to any of our emails, texts or calls regarding previous peak events that summer. For a little background information, this client had experienced some price spikes in the previous January so they were very keen on finding ways to cut future energy costs.

When they signed with us, we explained the benefits of peak load management and got them into a capacity pass-through purchasing strategy so they were able to curtail that summer. They did have some prior experience curtailing in a demand response program so they understood the concept and value of capacity management.

Because of all of this, we were a little surprised we hadn’t heard any confirmation from them so we continued to call, text, and email them all morning. Finally, at 12:30pm, we got a hold of the facilities manager and told him we expected the system to hit its peak between 5 and 6pm. He was very apologetic as they had been extremely busy with production over the last few weeks and had let our notifications fall by the wayside. Fortunately, he was well prepared with his curtailment plan and, after laying down our peak prediction for him, he immediately went to work!

The facilities manager completed a cost-benefit analysis and determined that it would be more beneficial for them to shut off their entire manufacturing, air-conditioning, HVAC system, and other facility machinery to manage capacity costs down than to continue manufacturing product that day. They ended up shutting down 94% of their entire operations!

The system hit its peak on July 30th from 5-6pm at 23,929.184 MW.

Because of their curtailment efforts, our client cut their capacity tag by 90%, which was the largest reduction we’ve ever seen! At the end of the day, they ended up saving $90,000 on their capacity costs over the course of 2020! As they far exceeding their curtailment and budget reducing goals, needless to say the manufacturer has continued to curtail this year (2020) to keep their capacity tag low going forward.

Whenever we tell this story to our prospective clients, this old quote comes to mind: “You can bring a horse to water, but you can’t make it drink”.

As energy consultants, we help our clients design tailored curtailment strategies as well as provide them with the accurate peak event predictions they need to be successful in their efforts, but we’re not on the front lines in their facilities; it’s up to them to implement their curtailment strategy at the right time. The reason this manufacturer was able to lower their demand and capacity tag so much was because they were well prepared and very proactive with their own strategy!

Contact us today to find out if your business could stand to benefit from peak load curtailment!

And, if you haven’t already, be sure to check out our other posts on capacity and capacity management: