What is capacity? It’s that pesky portion of your electricity supply bill, but do you really understand what it is and why you are paying so much for it?

Capacity makes up a large portion of your electricity supply price and, frankly, is a pretty confusing concept. However, once you fully understand capacity you can actually take steps to reduce the price you pay for it through a process called Peak Load Management!

More on that later, but first let’s walk through an example so you can grasp the idea behind capacity:

Looking at Capacity Differently

Say you have a retail store. When the holidays come around, you hire more staff to meet the increased demand of shoppers. To figure out how many people you should hire for the season and how to schedule their time to meet increased demand, you look at metrics from the previous year to see when the most people came into the store. This is all well and great, however, if less customers show up at these times than you had anticipated, you still have to pay the employees for their time in the store.

This is the concept behind capacity! It’s the amount of electricity a facility requires to operate (demand), but not the electricity commodity itself. The ISO calculates your building’s capacity so it can allocate enough electricity for your business to use at any given time.

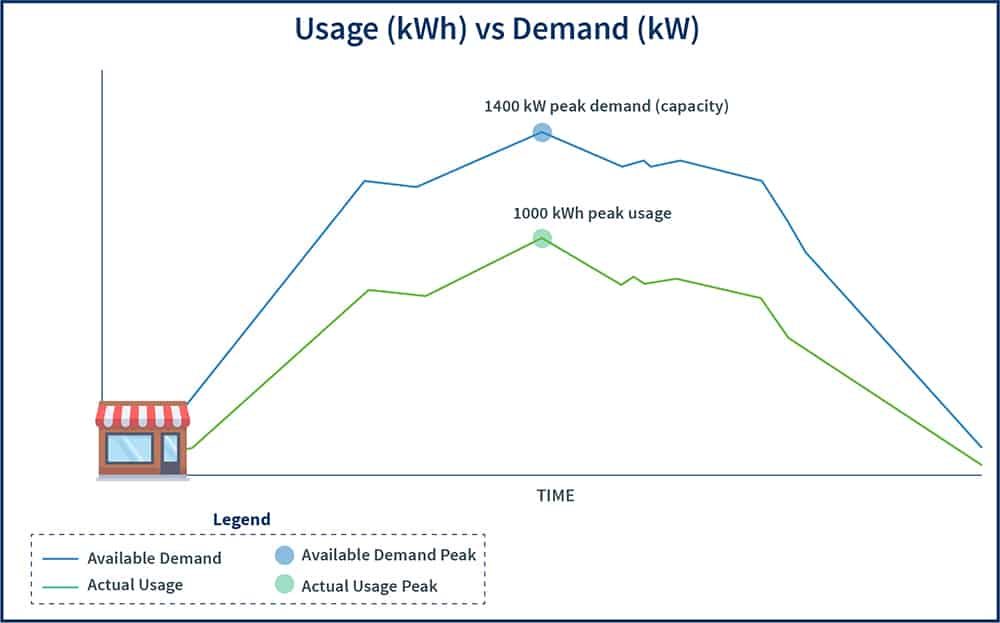

Diving in a little deeper to capacity, say your retail store is a 1,000 kW building. The ISO would set the capacity of a building with this type of demand at 1,400 kW to ensure that you have enough electricity available to use in case you use more than your standard 1,000 kW. You may not use the entire 1,400 kW, but you have the capacity for it just in case. This extra amount that you can use is called reserves or your capacity reserve margin.

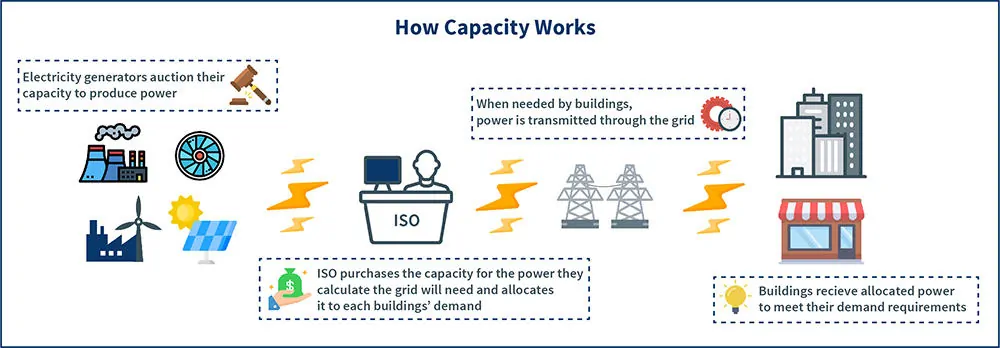

As your facility has its own capacity, so does every building on the grid as well as the entire grid itself. The ISO controls this and figures out how much capacity they need to meet peak load times (when the most electricity is being used) and then goes to auction to purchase it. They even tack in a little extra capacity in case there is unexpected usage, ensuring that the grid stays reliable.

Another portion of your capacity costs comes from the ISO purchasing a year’s worth of capacity for the grid through an auction with generators. This is allocated based on each building or account’s contribution to the peak load, i.e. what each account is using at the height of their operations. This is called your capacity obligation and it refers to the actual capacity your facility requires to operate reliably.

Back to the example, if your facility is using 1,000 kW during a peak event (time during the year when the grid is drawing the most power) and the whole system used 100,000 kW, you would be responsible for 1% of the capacity and, thus, 1% of the capacity costs.

How are Capacity Costs Determined?

The rate you pay for capacity (or your capacity tag) is set by the ISO.

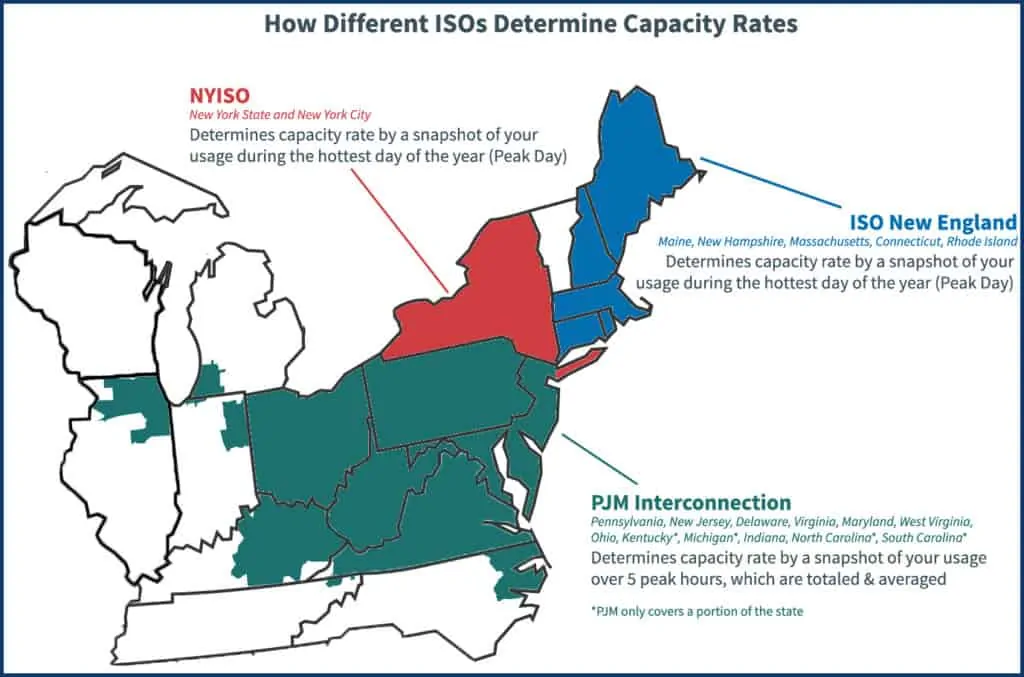

The largest factor in determining this price is your demand or need for electricity during periods when the most electricity is being drawn from the grid. These are called ‘peak events’ or ‘peak days’ and refer to times when the grid’s load reaches its maximum demand. The ISO takes a snapshot of this time from your electrical meter to determine your buildings’ max demand and, thus, your capacity tag for the following year.

These peak events usually occur during sustained heatwaves on consecutive weekdays during afternoon hours. While each ISO region uses some form of peak demand to calculate capacity costs, each one handles it slightly differently (see map above).

How Can I Cut Capacity Costs?

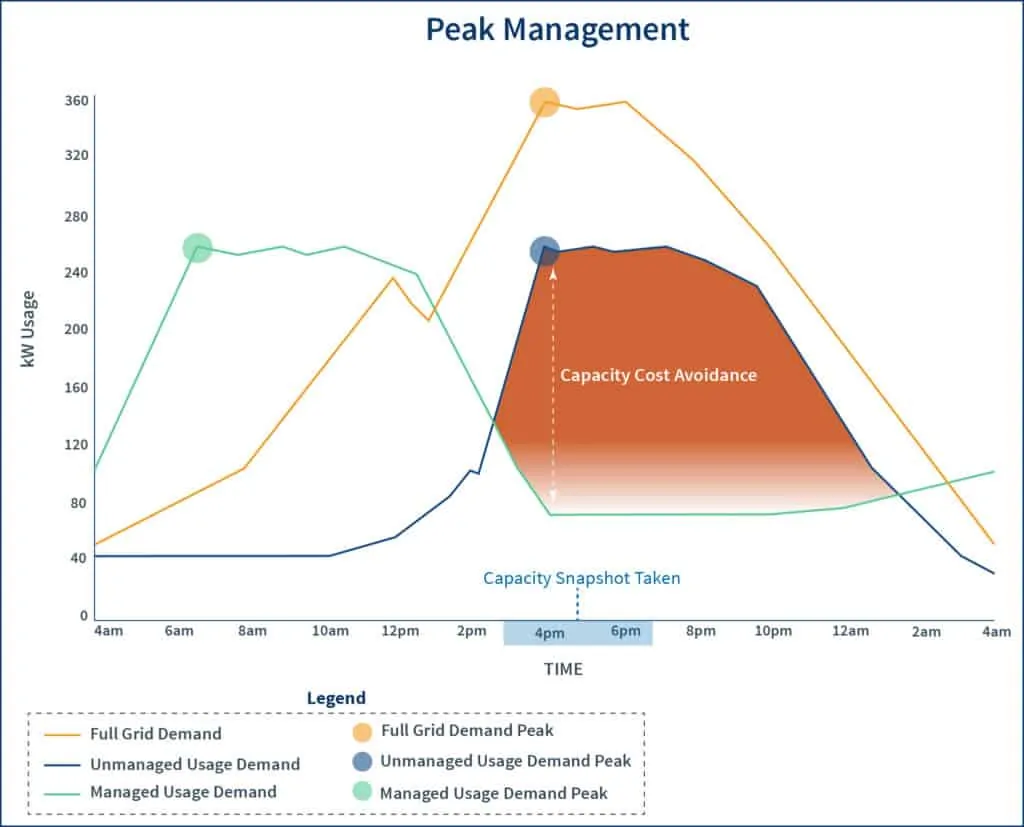

By curtailing your usage during these peak events you can lower what your demand looks like to the ISO and save significantly on your capacity costs for the following year. This is a process called Peak Load Management.

Because every business has different types of operations and goals to adhere to, Peak Load Management strategies work best when they are tailored to the business. Our Peak Notification Service works closely with our clients to fully understand their business and then develop a curtailment strategy that makes the most sense for them. We then alert you of incoming peak events so you can deploy your strategy at the right time to lower your demand snapshot and, thus, the price you pay for capacity for the next year.

To find out more about Peak Load Management and how it could help your business save on capacity costs, contact us today.